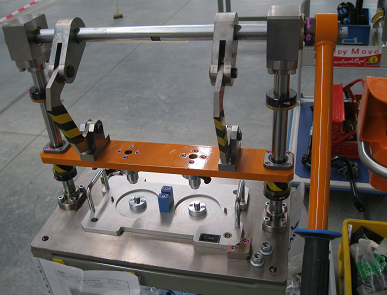

Precision assembly jigs – The company process the jigs

What is assembly jig?

Assembly jigs are fixtures used to locate and fix parts or products during assembly.

Designing unit, assembly jigs

Anttek Vietnam is specialized in designing, processing all kinds of jigs according to customer requirements to help customers optimize production and improve work quality.

To get order of the best quote, pls contact us:

Anttek Viet Nam equipment JSC

Hotline: 0988.688.336

Some kinds of industrial assembly jigs

Based on the assembly product, the jigs are divided into 2 types:

1. Universal assembly jigs: often used in assembly of single goods and small quantity goods. Can be used for many different parts or products, for example, assembly tables, V blocks, jigs, jacks, other auxiliary structures (pads, wedges, clamps, screw threads, etc. ).2. Specialized assembly jigs: used widely in mass production. for assembling fixed tasks and for a fixed part or product. Based on the functions of use, specialized jigs are divided into 2 types:

Assembly jigs are used to fasten a part or part of a product during assembly.

Assembly jigs are used to precisely fix assembly objects.

The structure of assembly jigs.

1. Body fixtures.2. Clappers positioning.

3. Clamping mechanism.

4. Other auxiliary structures.

Functions of jigs

The assembly jigs make the assembly process easier and faster. Furthermore it saves time and reduces technical requirements towards automation.

Principle of the assembly jigs

Put the base details (product body, base range, ...) on the jigAssign the base detail to the positioning parts of the jig

Clamp the part firmly with the clamping mechanism of the jig

Assembly other details to facilities detail.

Thanks for joining us!