What is a milling jaw?

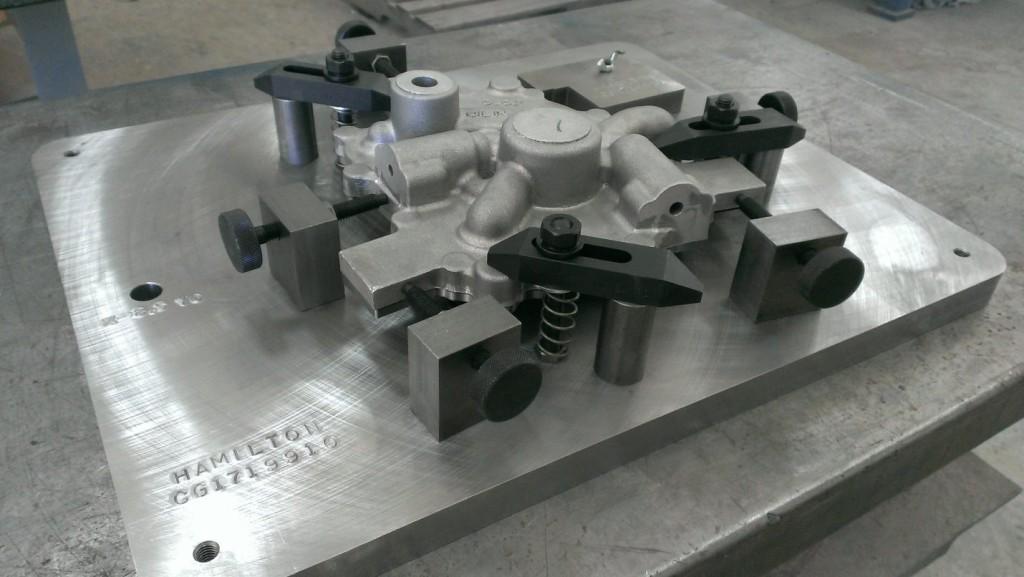

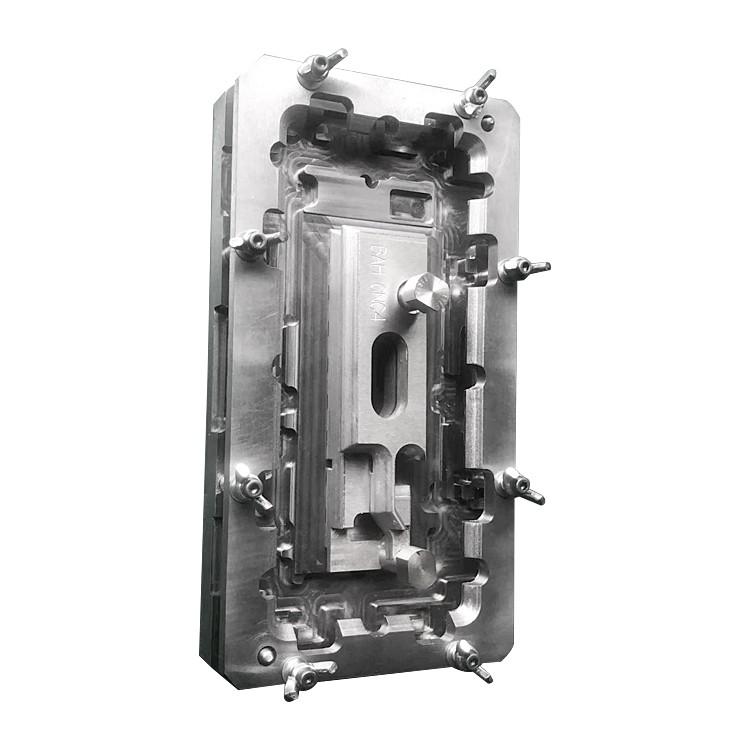

All types of jigs that are machined on a milling machine are called milling jigs. The jigs are usually made up of common parts: positioning elements, clamping parts, guide parts, jigs' housings, and also including a number of special details such as a pin, a knife size. , compared to the knife.

In addition, small details such as guide latch, gauge and tool holders.

- The jig requires a hard, solid process because the milling process will be affected by strong impulses.

-There are different types of jigs according to the criteria such as single or multiple details, counter knife direction.

2. The company specializes in designing milling jigs.

Anttek Vietnam is a company specializing in designing and manufacturing milling jigs according to customer requirements which was made by experienced engineer who was trained in Janpanes. and training engineers who have designed more than 600 different jigs for more than 120 businesses in Vietnam

Contact to order, drawings, quotes design fixtures:

Hotline: 0968 116 229 - 086 998 2628 - 0243 994 2628

3. Some special parts of the milling fixture

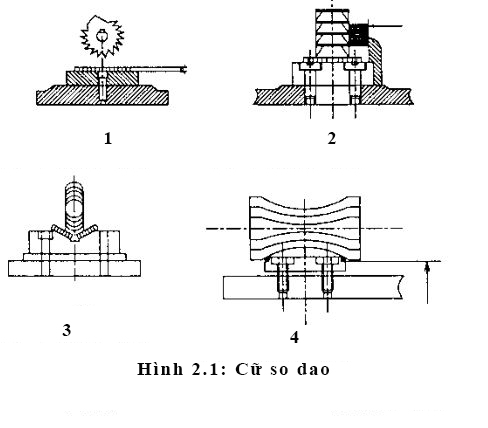

a. Knife

The tool (Fig. 3.1) works to determine the exact position of the milling cutter with the workpiece

Different types of knives:

- Flat tool: Works according to a specific method to locate the knife

- Corner tool: Locates the milling knife by two different methods.

- Perpendicular cutter: To determine the position of the milling cutter.

These tools require stiffness and flexibility, so they will be designed by Steel and hardened to around 60-70 HRC.

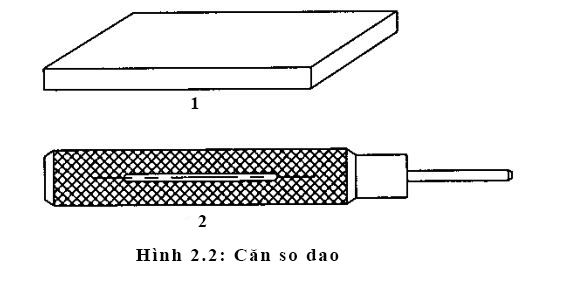

b. Align the knife

The tool alignment is an important detail, the intermediary role between the milling tool in the tool comparison.

2 special types of knife bases:

- Flat alignment (Figure 2.2-1)

- Aligning chopsticks (Figure 2.2-2)

3. Anttek typical milling jigs

* Tailed-end milling jigs

a. Structure and working principle

Described in Figure 2.3

The jig (1) is fixed on the milling table which is oriented by 2 latch (2), the positioning block (3) is fastened with the milling jig body (1), the Ta-ro billet will be placed. exactly on the positioning block and tighten on the gear (4), the clamping speed (5) clamp the working part of the tapper. The tail of the speed will be placed on the pin (6), the tapper is clamped tightly with the eccentric wheel (7) and blow (8), using two milling cutters to simultaneously machined the two sides of the tapper's tail, to process the remaining two edges, the workpiece is removed from the blow (8) and turned to 90 degrees.

b. Positioning method

+ The pillars of the tail will be located on the long positioning block to eliminate four degrees of freedom (OZ-; OY-; OZ; OY).

+ The tail of the Ta-rô resting on the (4) reducing one degree of freedom (OX-) when the speed of clamping the tapper against the latch (6) eliminating the remaining degree of freedom (OX) is completely fixed

Anttek Equipment JSC specializes in designing jigs and consulting with long experience to bring the most effective jig design.

Repeatability, accuracy, and interchangeability in the manufacturing of products: độ lặp lại, chính xác và khả năng thay thế trong sản xuất sản phẩm.