What is SMT? SMT - surface mount technology is indispensable in manufacturing electronic products and devices such as Laptops, desktop computers, smart TVs, smartphones, computers, tablets,... So what is SMT? Advantages and disadvantages of SMT.

What is SMT? SMT (Surface-Mount Technology) or surface mount technology is a method for attaching electrical components directly to the surface of a printed circuit board, or PCB. This process allows manufacturers to automatically complete more of the assembly required to create a workbench. It reduces production costs and maximizes output by eliminating bottlenecks on the assembly line. SMT has another major advantage over the previous “through-hole technology” method. In the older form, electronic components were attached to a circuit board through holes specifically drilled into the board for the component. This requires more significant components, precision handling, and the addition of a solder to attach each component securely.

SMT aids the formation of smaller PCB designs by allowing for higher component densities, giving designers more data to work with. In the SMT process, components can be reached on both sides of the circuit board, increasing parts per unit area.

SMT process, components can be placed on both sides of the circuit board, increasing the parts per unit area.

SMT-assembled PCBs can transmit high-speed signals due to shorter connection lengths and small latency.

SMT is the preferred solution for automated assembly with some positioners capable of placing more than 136,000 parts per hour.

Due to its compact package and lower conductive induction, it has a smaller radiated ring area and thus better electromagnetic compatibility (EMC).

Surface mount technology is not a defect-free process and poses unique challenges. While components can be placed faster, the machinery required to do so is very expensive. Therefore, although the board assembly costs are lower, the initial investment in the assembly process increases significantly.

Manual assembly and repair are difficult and require expensive tools and a skilled operator.

Many SMT components are not socket compatible.

SMT also introduces the possibility of misaligning components, which is less likely in the case of through holes. In through-hole, once the conductors pass through the holes, the components are fully aligned and cannot move out of place. However, SMT components can be misaligned if not handled with great care.

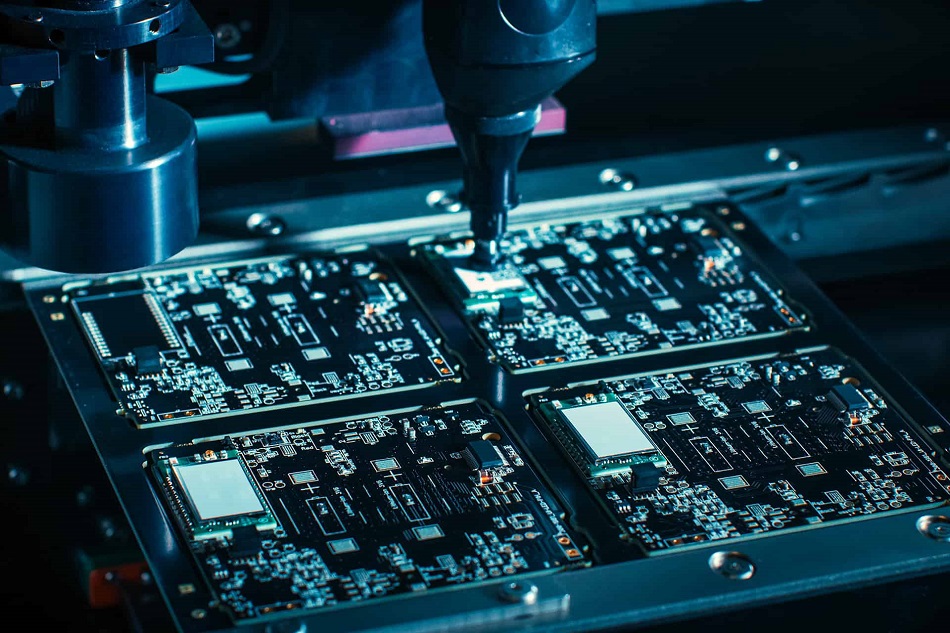

SMT is a method of using specialized tools to manage small components on printed circuit boards. While this process can be done by hand, it is extremely time-consuming and tedious. So most of the production and assembly of SMT is done through automation.

The process starts with a pile of components and any kind of printed circuit board. PCBs are usually covered in solder pads made of tin, silver, or gold plating. Then cover the solder pad with stainless steel or nickel welding tape. Once the solder pad is in place, the PCB is brought down the assembly line to pick and place machines that take the components from the conveyor and place them where they need to be on the PCB. The board is then passed through a reheated furnace, where it is exposed to infrared radiation. The contact leads to the melting of the solder paste and the formation of solder joints.

After that, the PCB must undergo many quality checks, including component alignment and solder bridge testing. In the case of a two-sided circuit board, the printing, placing, and re-alignment process can be repeated using solder paste or glue to hold the components in place.

SMT is used to create the assemblies used in most of the electronic equipment in the world. From digital cameras and smart TVs to laptops, desktops, and smartphones, SMT has paved the way for circuit boards to work with better and more functionality.

Anytime a product needs a circuit board for electronic functionality, SMT is used to create it. The density at which components can be placed is without real competition.

Here are some products where you can find the SMT processor board:

Laptop

Desktop

Smart TVs

Smartphones

Tablet

Electricity toys

Robots

VR headsets

Smart Devices

What is SMT? Surface mount technology, SMT, and its related surface mount devices, greatly accelerate the assembly of PCBs and simply on-board components. SMT allows manufacturers to automatically complete more of the assembly required to create a workbench. It reduces production costs and maximizes output by eliminating bottlenecks on the assembly line. Because of this benefit, SMT is widely applied in the current electronic circuit board manufacturing industry.